ETO exhaust gas treatment equipment

- Negotiate price

- RongFeng

- China · Hebei

- 15~90 days

Product Information

Product introduction

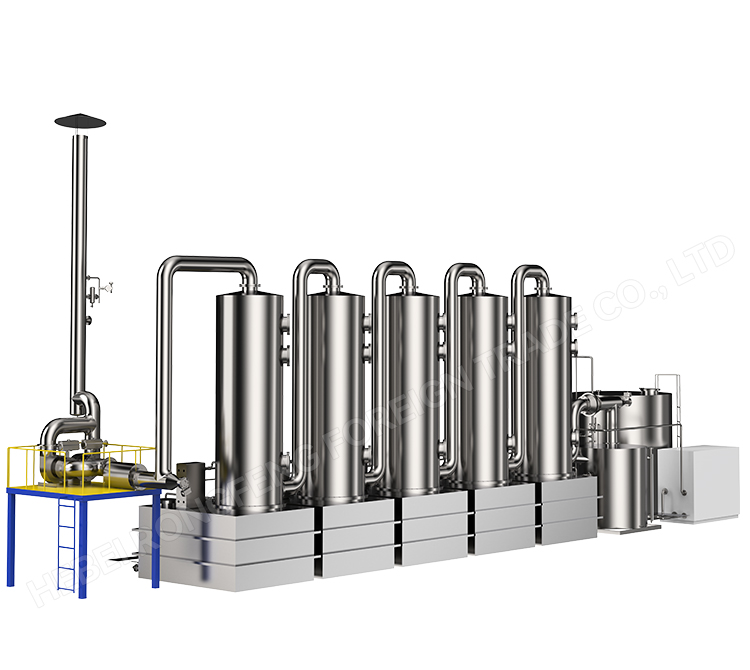

he Rongfeng ethylene oxide post-treatment equipment selects a new type of catalytic coupling water absorption process. Through the action of the catalyst, high-concentration and low-boiling-point ethylene oxide is converted into ethylene glycol with high boiling point and extremely strong water solubility. This not only greatly improves the absorption and purification rate of ethylene oxide tail gas, but also can sell the ethylene glycol solution generated after the tail gas treatment for the second time for resource utilization, reducing the harm to the environment and turning waste into treasure. When the sterilizer finishes sterilization, the residual ethylene oxide in the sterilization cabinet is extracted through a vacuum pump. First, the discharged ethylene oxide is pumped into the catalytic coupling absorption tower of the waste gas treatment system. In the absorption tower, ethylene oxide is fully absorbed by the aqueous solution containing the acid catalyst, and the purification rate of ethylene oxide waste gas is greater than 99%.

This equipment is generally composed of: steam-water separator, spray main equipment (including spray tower, reaction tower kettle and PP filler, etc.), circulating pump (including spray pump, rich night pump and vacuum pump water supply pump), storage tank, chiller, high-pressure fan, control system and sensors (temperature, pressure, ethylene glycol density, pH meter, liquid level sensor and EO detector), etc.

Product characteristics

1. The removal rate after tail gas purification reaches more than 99.9%, and the treatment effect can reach below 2 ppm, usually treated below 50 ppm.

2. The weak negative pressure design at the outlet of the sterilization vacuum system ensures that the system does not affect the operation of the sterilizer cabinet.

3. Automatic control system, the whole control is linked with the ethylene oxide sterilizer and the resolution room to operate, without manual intervention, and automatic fault diagnosis and fault reminder.

4. The frequency conversion control system is adopted, and the fan speed is automatically adjusted according to the emission amount of multiple sterilizers and the emission air volume of the resolution room.

5. Hydration absorption reaction, safe and reliable, no toxic gas is generated, and there is no explosion danger.

6. The water saving rate reaches 99%, prolonging the service life of the vacuum.

7. Professional design and planning according to the customer's site.

8. The equipment has a simple structure, strong practicability, and low operating cost.

9. There is no any wastewater discharge, and our factory can assist in contacting the third-party recycling company for the ethylene glycol solution.

10. Multiple equipment materials and catalyst forms are available for customers to choose.

11. The electric control and its electrical components are all explosion-proof designs with high safety performance.

12. There is an online EO concentration monitoring device installed at the discharge outlet, which can monitor the EO discharge concentration in real time.

13. Strong cooperation with the Catalytic Research Institute of Zhejiang University of Technology, and continuous innovation and breakthroughs.