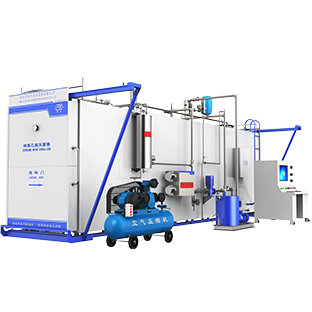

Ethylene oxide sterilizer

- Negotiate price

- RongFeng

- China · Hebei

- 15~90 days

Product Information

Principle of product

Ethylene oxide sterilizer is a special equipment for low temperature fumigation and sterilization of the articles enclosed in the sterilization room with ethylene oxide gas under certain temperature, pressure and humidity conditions. It has a broad spectrum of sterilization, strong penetration (cloth, carton, polyethylene film can penetrate), sterilization thoroughly, no damage to the articles, easy to preserve after sterilization and other advantages.

The HMQ large ethylene oxide sterilizer developed and produced by our company is mainly composed of sterilizer cabinet, auxiliary equipment (heating and thermal circulation device, vacuum device, dosing and gasification device, humidification device, sealing device, residual gas treatment device), monitoring and control device.

Product Features

1.The cabinet body is made of pressure vessel grade plate, designed and produced according to the process of pressure vessel to ensure the pressure bearing capacity and 20 years of service life.

2.Customized equipment according to customer needs, plant area and output, support customized size, cross-sectional area, configuration, door body (lifting/sliding/revolving).

3.Using hexahedral hot water circulation heating mode, sterilization without dead corners effectively provide the uniformity of temperature and humidity in the sterilization cabinet.

4.Support automatic, semi-automatic intelligent control, voice prompts operation, has a good human-computer interaction interface, can achieve parameters release standards.

5.With over temperature, over pressure, EO non-vaporization and other real-time monitoring devices, improve the type of fault judgment, automatic alarm, safer use.

6.Each port of the dosing pipeline can be disassembled for easy cleaning of the pipeline. The drainage ball valve is provided to facilitate replacement of circulating water and cleaning of the water jacket.

Technical parameters

1.inner tank volume:1m³-100m³

2.temperature control range:0~100℃

3.pressure control range:±80kpa

4.humidifier maximum power:3~24kw

5.cabinet material:SUS 304 stainless steel

6.humidity control range:0~99%RH

7.electric heating maximum power:9~60kw

8.power supply:three phase five wire 380V; 50Hz